The Technology

Magnetron and HiTUS® sputtering

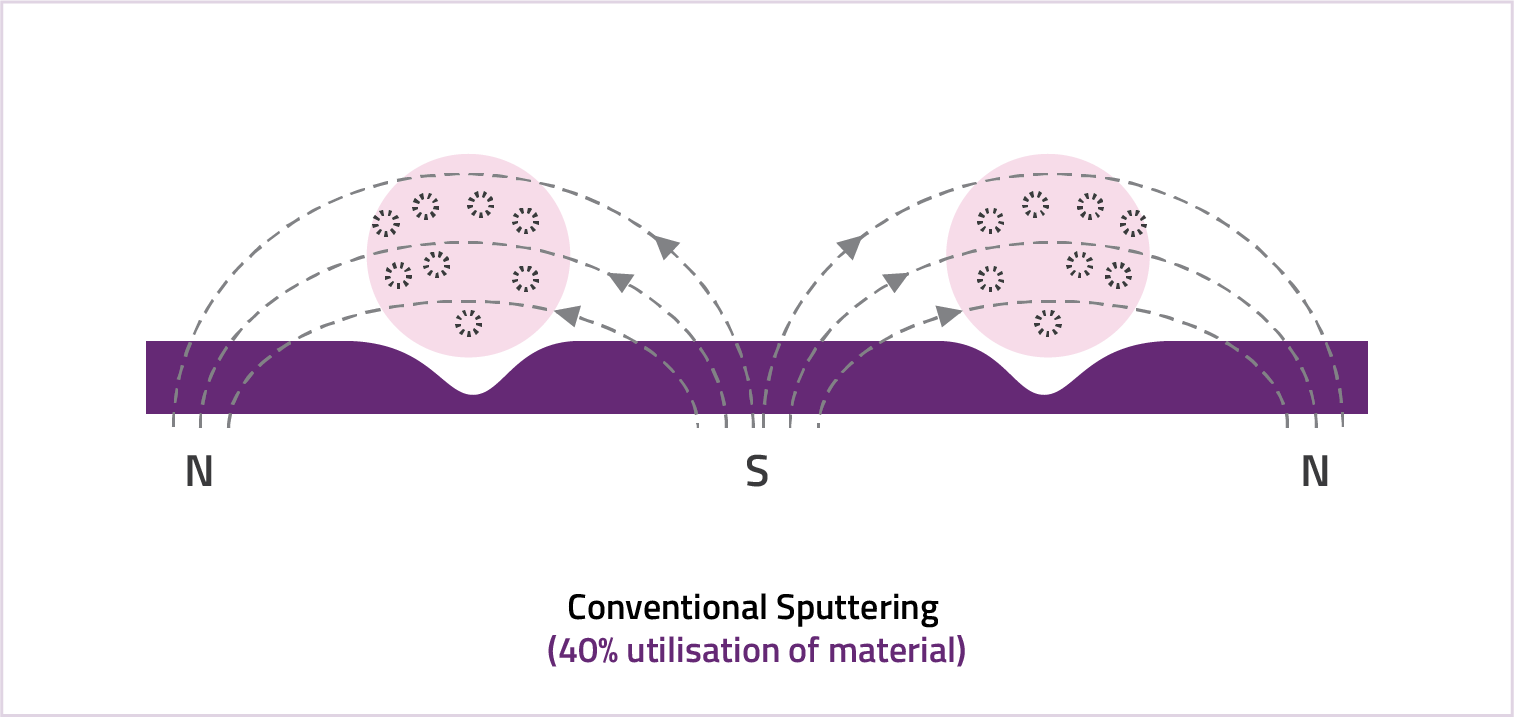

The fundamental difference between Magnetron sputtering and HiTUS® is that HiTUS® does not require target bias to strike a plasma. It benefits from a remotely generated plasma which offers advantages over conventional sputtering. An RF powered antenna coupled with a DC magnetic field results in a magnetised, high density and uniform plasma which, with application of a bias voltage to the target, results in almost full surface erosion of target source materials (this eliminates the racetrack profile as seen in magnetron sputtering). The ion density (controlled by the plasma source RF) and the ion energy (controlled by the target bias) are independent of each other giving us a much wider sputter parameter space for the high rate deposition of both existing and new or complex materials.

The Plasma Source

The High Target Utilisation Sputtering (HiTUS®) technology produces a high density low energy magnetised plasma (ion density > 1013 cm-3 and ion energy <10 eV) without the requirement of a target to strike or maintain the plasma.

Remote Plasma Sputtering

Efficient, uniform high rate sputtering only occurs upon the application of a sufficient target bias (DC, pulsed DC or RF) to accelerate the initially low energy ions into the target surface. As the plasma is not driven by the target, the plasma density and target ion energy can be controlled independently.

Ionised Physical Vapour Deposition (iPVD)

A significant fraction of the sputter flux is continuously ionised by the high density plasma and therefore remote plasma sputtering is inherently an iPVD process. Substrate biasing can be used to control the energy and direction of the ionised sputter flux to enable the coating of high aspect ratio trenches and vias and improve film coverage in normally inaccessible shadow regions by re-sputtering during deposition.

Substrate Interactions

The magnetised plasma interacts with the substrate coating process in an atypical and beneficial manner compared to conventional sputter processes. An optimal balance of plasma density and deposition rate may be set to deliver a low energy ‘plasma assist’ to the deposition process without the need for substrate bias. This beneficially impacts the thin film coating properties and enhances reactive deposition processes thereby resulting in the ability to coat fast deposition rate, high density films on to temperature sensitive polymeric substrates.

Sputtering Basics

Click below to see the difference between conventional sputtering and HiTUS® sputtering.